Holographic Digital Twin Technology

Click the blue buttons below to switch between different 3D scenes.

Axiom Holographics is at the forefront of innovation, combining the power of digital twins with the immersive capabilities of holography. Our cutting-edge digital twin technology allows you to step into a world where virtual replicas of physical objects and systems come to life in stunning, three-dimensional holographic displays.

Holographic digital twin technology combines the digital twin concept and holography to create a digital model of physical objects or systems. A digital twin is a virtual replica of a real-world object or system that enables real-time monitoring, analysis, and simulation.

Axiom Holographics provides devices containing digital twin software to create a digital twin or digital process twin in a three-dimensional manner, enabling you to interact with and visualise complex data more intuitively and realistically.

3D digital twins technology can be used to visualise and simulate building designs, provide real-time insights into production processes, virtual copies of your local municipality so you can plan out new building works or public services, and so much more in a virtual environment. Elevate your business by adopting this digital transformation for models and simulations.

INDUSTRY PARTNERS:

Stakeholders in the approval and review process don’t share the context that the engineers and architects have. Showing visual representations of plans in 3D in an interactive medium is invaluable in the review process, both with collaborators and decision-makers – and digital twin technology allows you to do just that. Interrogate 3D CAD data or other models and explore every angle. Multiple people can work together and walk through full-sized CAD or polygon-based models or explore designs in 3D without wearing bulky VR headsets.

CAD assets and other 3D models can be combined with laser scans and photogrammetry data; any-size point cloud models can be instantly loaded alongside your assets. This is invaluable for obtaining complete context of the area surrounding a project or comparing as-built constructions against computer designs. Use our powerful Presentation-building tools to further drive understanding, from measuring and label features to toggling layers and sections of models in real-time.

Our Hologram Tables project holograms of cities up to 70cm high, and the level of detail available is limited only by the data you provide. You can include live feeds of planes, cars, transit or other real-time information to annotate your visualisations. Adding multiple objects and preparing full presentations are a breeze & holograms are the most futuristic way to plan and display large-scale designs. Integration with our hologram devices is possible via our coding and scripting APIs.

Digital Twin 3D Model Devices

We offer a range of devices for you to present digital twin data.

Hologram Table

With our world-first, multi-user Hologram Table, you can gather around and directly engage with the digital twin, manipulating and exploring the virtual model. This hands-on approach fosters teamwork, communication, and knowledge sharing, making it ideal for collaborative problem-solving, training sessions, or project discussions.

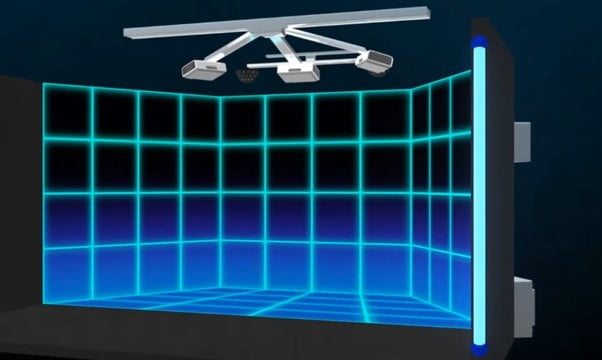

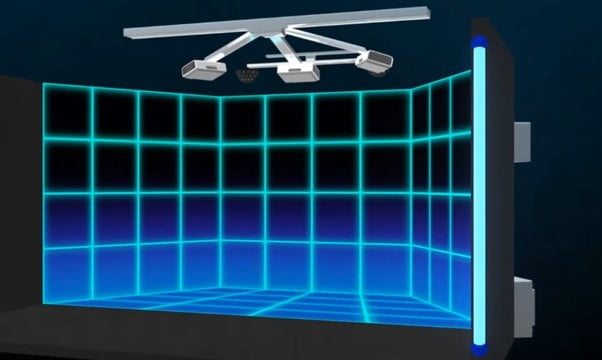

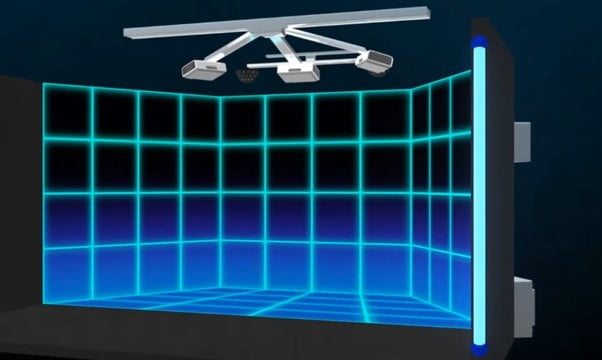

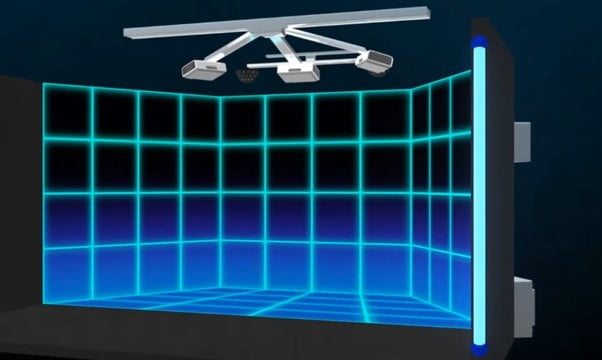

Hologram Room

Step into a world where virtual replicas of an actual physical object or system come to life in stunning, three-dimensional displays. Digital twin technology can be fully harnessed with our Hologram Room, enabling you to interact and explore the virtual representation from all angles.

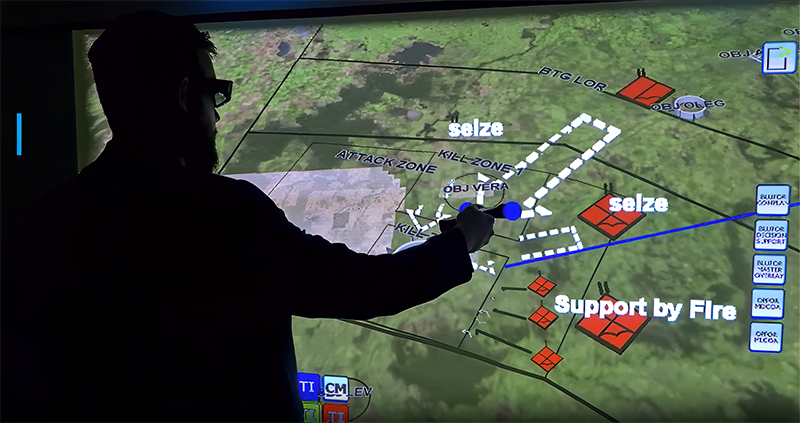

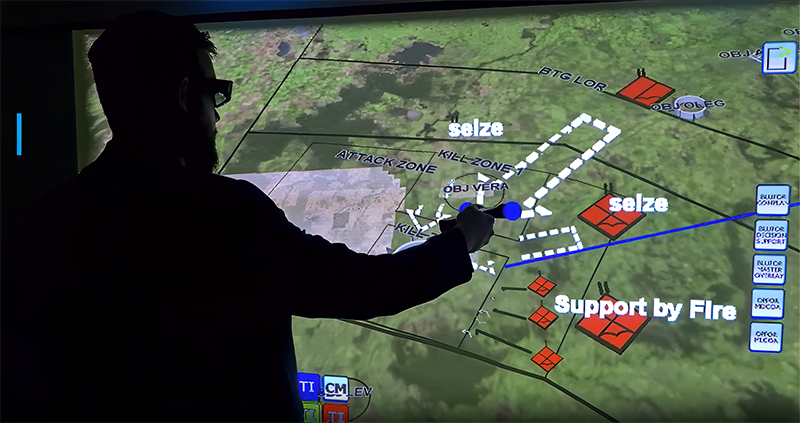

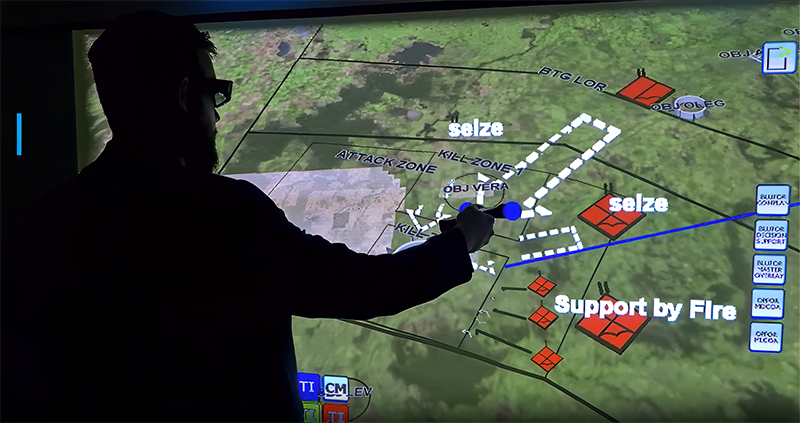

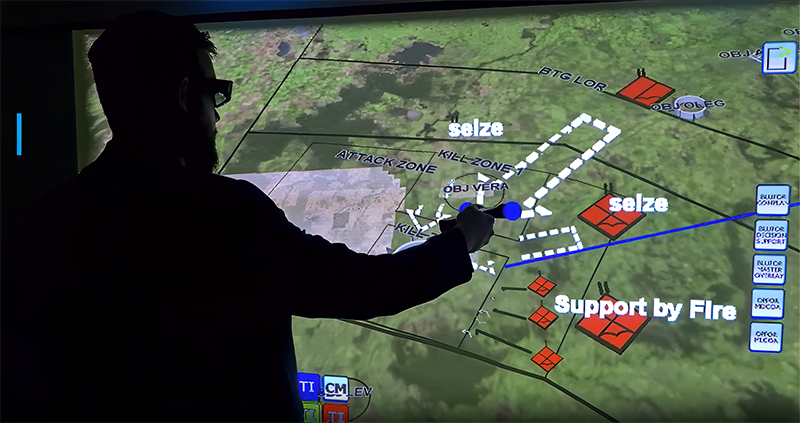

Hologram Wall

Our Hologram Wall can project digital twins in a life-sized format, enabling users to create digital models or systems and visualise complex data in great detail. This device provides a powerful platform for digital twin technology, offering large-scale visualisation, interactive engagement, collaborative opportunities, and real-time data integration.

Hologram Table

With our world-first, multi-user Hologram Table, you can gather around and directly engage with the digital twin, manipulating and exploring the virtual model. This hands-on approach fosters teamwork, communication, and knowledge sharing, making it ideal for collaborative problem-solving, training sessions, or project discussions.

Hologram Room

Step into a world where virtual replicas of an actual physical object or system come to life in stunning, three-dimensional displays. Digital twin technology can be fully harnessed with our Hologram Room, enabling you to interact and explore the virtual representation from all angles.

Hologram Wall

Our Hologram Wall can project digital twins in a life-sized format, enabling users to create digital models or systems and visualise complex data in great detail. This device provides a powerful platform for digital twin technology, offering large-scale visualisation, interactive engagement, collaborative opportunities, and real-time data integration.

What is a Digital Twin?

Digital twin modeling and simulation refer to virtual representations of a real-world entity or system. This concept can be applied in various industries, including manufacturing, healthcare, urban planning, and more. A digital twin encompasses both the physical and functional aspects of the entity it represents, providing a comprehensive and real-time reflection.

Developing digital twins involves a multi-faceted process that integrates cutting-edge technologies to create accurate and dynamic virtual representations of real-world entities.

Key features of digital twins include:

Virtual Representation

A digital twin replicates the physical attributes and characteristics of its real-world counterpart in a virtual environment.

Real-time Data Integration: Digital twins are connected to sensors and other data sources, enabling the continuous exchange of real-time information between the physical entity and its digital counterpart.

Interactivity

Users can interact with digital twins to monitor, analyse, and simulate different scenarios. This interactivity facilitates decision-making and optimisation.

Simulation and Analysis

Digital twins allow for the simulation and analysis of various conditions, behaviours, and performance metrics. This capability aids in predicting outcomes and optimising the real-world system. Digital twin simulation empowers stakeholders to explore, predict, and optimise complex scenarios, providing a virtual playground for informed decision-making and continuous system enhancement from the data collected.

Monitoring and Maintenance

Industries use digital twins to monitor the status and performance of physical assets. This proactive monitoring facilitates predictive maintenance and helps prevent unexpected failures. For example, in manufacturing, a digital twin of a physical product can be created to simulate its production process, test different design iterations, and monitor its performance in real-time. Similarly, in healthcare, the digital version of an organ can assist in personalised treatment planning and monitoring.

Digital twin software plays a pivotal role in modern industries by providing a comprehensive platform to create digital twins of physical assets or processes. This innovative technology integrates a variety of data types, including industrial data, performance data, and operational data, to generate accurate and dynamic virtual replicas. Industrial data forms the backbone of digital twin creation, encompassing information from sensors, machinery, and other sources specific to the industry. This detailed dataset is instrumental in replicating the physical entity in a virtual environment.

As digital twin software combines performance data with real-time updates, users gain a holistic view of how the corresponding real-world system operates. This allows for in-depth analysis, identification of inefficiencies, and the optimisation of processes based on actual performance metrics.

One of the key advantages of digital twin software is its ability to capture relevant data. This includes not only information crucial for immediate monitoring and control but also data essential for predictive analysis. By integrating a diverse range of relevant data, the digital twin becomes a powerful tool for forecasting trends, anticipating issues, and mitigating operational risks.

The concept of digital twins continues to evolve with advancements in technology, including the integration of artificial intelligence and advanced analytics, providing a more sophisticated and comprehensive representation of physical entities in the digital realm.

3D Digital Twin Technology FAQs

Essentially, digital twins are just a digital representation of physical objects or systems in a three-dimensional digital environment. Creating a digital twin involves meticulously mapping and replicating both the physical attributes and functional behaviours of a real-world entity in a virtual environment, paving the way for dynamic simulations and insightful analyses.

Our holographic digital twins utilise holographic displays to project a digital twin prototype (the virtual replica of the object or system) to simulate and analyse the behaviour, performance, and interactions of the physical counterpart in a virtual environment.

The rapid growth of the digital twin market is driven by the increasing demand for advanced technologies that enable organisations to improve analysis, optimisation and decision-making. For this reason, holographic digital twin technology offers several benefits, including enhanced visualisation, immersive experiences, and intuitive interaction. They allow for better understanding and analysis of complex data, enable collaborative decision-making, and facilitate real-time monitoring and simulation of physical objects or systems.

Digital twin software, with its powerful integration of data and advanced capabilities, significantly contributes to mitigating operational risk in a wide range of industries with the incorporation of machine learning and their efficiency in infrastructure management. By leveraging real-time insights from industrial data and performance data, organisations can proactively identify potential risks, allowing for timely intervention and strategic decision-making.

Holographic digital twin application is used across various industries, including architecture, engineering, manufacturing, healthcare, transportation, and entertainment. They can be used for design visualisation, enhancement of business processes training simulations, tactical planning, and more.

Yes, historical data can be combined with real-time data in a 3D digital twin model. The integration of real-time data streams with historical data provides a dynamic and comprehensive view of the object or system’s current and past states.

Yes, holographic digital twin technology has the potential to revolutionise collaboration. Our holographic devices provide a shared, immersive environment where users from different locations can interact with and manipulate holographic representations of physical systems, fostering collaborative decision-making.

Security is a crucial aspect, and holographic digital twins must implement powerful measures to protect sensitive data and prevent unauthorised access. Encryption, authentication protocols, and secure network connections are some of the security features integrated into holographic digital twin software.

Contact Us

Get in touch with us to discuss your digital twin modeling and simulation needs.